Are Nuisance Alarms Limiting Your Production Capacity?

What do Alarms 410, 426, 700, 2106, and 2118 have in common?

These Alarms:

- Reoccur regularly – as often as 3-4 times per week

- Trigger both automatic and manual system resets

- Occur at the peak of the power curve (during high wind conditions)

- Result in lost power and revenue generating opportunities

- Impose unnecessary wear on assets

Gamesa turbine operators might say these Alarms are only a nuisance, but even a short Automatic Reset is creating downtime for your fleet, which reduces Availability. This effect is magnified because these Alarms are most likely to occur during peak operating conditions – high winds – when performance matters the most, costing even more MWhs.

Another complicating factor is that the OEM SCADA and diagnostics manual have assigned these Alarms to different subsystem, as shown in Table 1, which causes further confusion in true diagnosis.

Table 1: Subsystems assigned to Alarms by OEM SCADA and diagnostics manual.

Alarm Number | Description | Subsystem Associated by the OEM |

410 | Overspeed Guard System Activation | Gearbox |

2118 | Interbus Communication Error | PLC Hardware |

2106 | Temperature Module Failure | PLC Hardware |

700 | PLC-Converter Communication Failure | Communications |

426 | Rotor Speed Sensor Error | Gearbox |

Resolving Issues with Unrelated Alarms

Alarms 410, 426, 700, 2106, and 2118 are not as unrelated as the OEM manuals suggest. As a judicious operator, you know that environmental operating conditions have a major impact on the frequency of these Alarms.

High winds create the perfect conditions for static build-up in the turbine blades. If this static is not discharged safely, one or more of these five Alarms is likely to be triggered.

The Problem with Static

In the best case, static build-up in an ungrounded turbine triggers an Automatic Reset. In the worst case, a Local Reset is required. This could mean several hours of downtime and lost production at the peak of the power curve, when the asset should be generating the highest returns.

Ultimately, any amount of lost production time created by static Alarms results in lost revenue. Unplanned resets also affect electronic components up and down the line, as the entire system undergoes a hard reset. Further, a manual reset increases operator cost and liability through unproductive activity and unnecessary exposure because technicians need to be deployed to reset or repair asset damage that could have been prevented.

Continuous Grounding Eliminates Static

By providing a continuous grounding path for the blade to discharge static electricity, AP Renewables’ Static+Lightning Protection System (SLPS) prevents build-up of static and therefore neutralizes the grounding spikes that occur as a result of sudden discharge of the blade after breakdown and ionization of the air insulation gap in the OEM’s subpar Lightning Protection System.

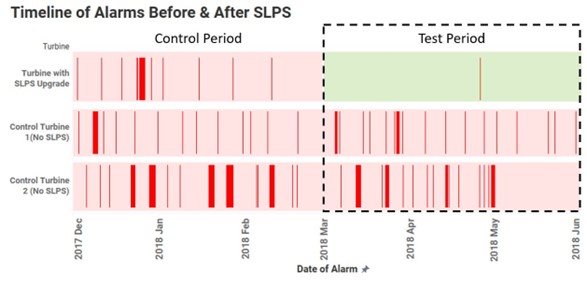

The SLPS has been engineered to provide continuous grounding for Gamesa models G80, G83, G87, G97, and G114. Figure 1 shows an example of field test data from a Gamesa turbine with the SLPS installed along data from two control turbines (no SLPS upgrade).

Figure 1: Field test data comparing the performance of the turbine with the SLPS upgrade (top row) with the two control turbines. Occurrences of Alarms 410, 426 700, 2106, and 2118 for each turbine are indicated by red bars, where the width of

During the nine-month control period, all three turbines showed a high frequency of nuisance Alarms 410, 426, 700, 2106, and 2118 – with an average of six Alarms per month. Figure 1 shows a sample of the data recorded from three turbines during three months of the control period (December 1, 2017 to February 28, 2018).

During the three-month test period (between March 1 and May 31, 2018), the control turbines continued to produce an average of six nuisance Alarms per month. In comparison, the test turbine with the SLPS upgrade installed experienced only one nuisance Alarm during the entire three months (upper right corner of Figure 1).

Signs of a turbine with grounding problems include:

- Alarms 2118 Interbus Communication Problem

- Alarm 2106 Temperature module fault

- Alarm 700 Converter Communication Fault

- Alarm 426 Rotor speed problem* when it is correlated to weather

- Higher than expected cost of Phoenix Contact® PLC modules

Eliminate Static and Increase Production

With the SLPS installed, the wind turbine blades drain their static electricity in a continuous trickle of controlled current to the tower grounds and away from the turbine electrical and mechanical systems. Without the SLPS, the repeated and sudden discharge causes ground spikes creating stress on turbine electronics, turbine yaw drives and nearly every other part of the asset.

Field tests have shown that the SLPS can increase Availability by up to 1.3%.

Because the effects of ungrounded static are most acute during the high wind conditions, the SLPS can safely eliminate Automatic Resets and increase your production capacity when asset Availability matters the most.

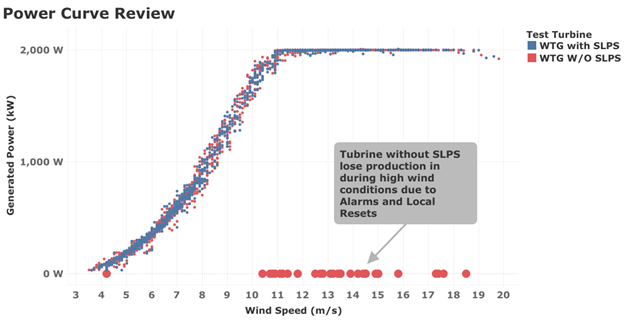

For typical 2 MW Gamesa turbine, the SPLS can generate an average of 1.8% AEP increase across the wind speeds range with high gains in the high wind regimes, as shown in Figure 2.

Figure 2: Active power generation as a function of wind speed for a 2 MW Gamesa turbine.

Increase AEP by 1.8%

For typical 2 MW Gamesa turbine, the SPLS can generate an average of 1.8% AEP increase across the wind speeds range with high gains in the high wind regimes

The SLPS has been tested for inland and near shore applications. Data shows how for inland turbines multiple Local Resets could be prevented during storm seasons by installing the SLPS in the Gamesa G80, G87, G90, G97 or G114 turbines. The SLPS is designed as a Level I Lightning Protection upgrade part and exceeds the latest IEC 61400-24 and US NFPA-780. The upgrade units exceed fire protection UV 94 V-0.

The SLPS has been independently tested to IEC 61400-24 level 1 at 200kA and 10 MJ/Ω energy resistance by world recognized lightening experts in wind, the PolyTech Laboratories of Denmark (former GLPS) and NTS Laboratories in the U.S. The SLPS can be easily and quickly installed on your existing Gamesa turbines.

To find out more about how the SLPS can increase the Availability and profitability of your fleet, contact AP Renewables.